Reliable Predictive Maintenance systems

We provide dedicated machine specific software to automatically self-diagnose asset deterioration and impending failure. It is based on algorithms developed over thirty years that are not offered by others.

Our Vision & Mission

Corporate Vision

To be the global leader in the Predictive Maintenance systems (asset diagnostics and prognostics) using a SaaS business model.

Corporate Mission

Develop, manufacture, and market cost attractive software for full time Predictive Maintenance and automated self-diagnostics of industrial and commercial assets.

Our value

Increased Efficiency & Reduced Chances of Storm.

At PredictOS, we specialize in delivering tailor-made, machine-specific software designed to autonomously detect and predict asset deterioration, as well as potential failures. Our cutting-edge technology is built upon three decades of algorithmic development that stands unparalleled in the industry.

Corporate Vision

To be the global leader in the Predictive Maintenance systems (asset diagnostics and prognostics) using a SaaS business model.

Corporate Mission

Develop, manufacture, and market cost attractive software for full time Predictive Maintenance and automated self-diagnostics of industrial and commercial assets.

Who we are

The ultimate software for Predictive Maintenance Systems.

Introducing “PredictOS” – Your Exclusive Source for Tailored Machine-Specific Software Enabling Automated Self-Diagnostics of Asset Decline and Imminent Breakdowns. Our cutting-edge algorithms, honed over three decades, stand unparalleled in the industry, setting us apart from any competition.

Decades of Algorithmic Expertise

Distinguished by algorithms honed over a span of three decades, we stand out from rivals, ensuring precision and dependability.

Paradigm Redefined

Our approach disrupts the conventional Predictive Maintenance paradigm, presenting a novel and enhanced method for superior results.

Applications and Products

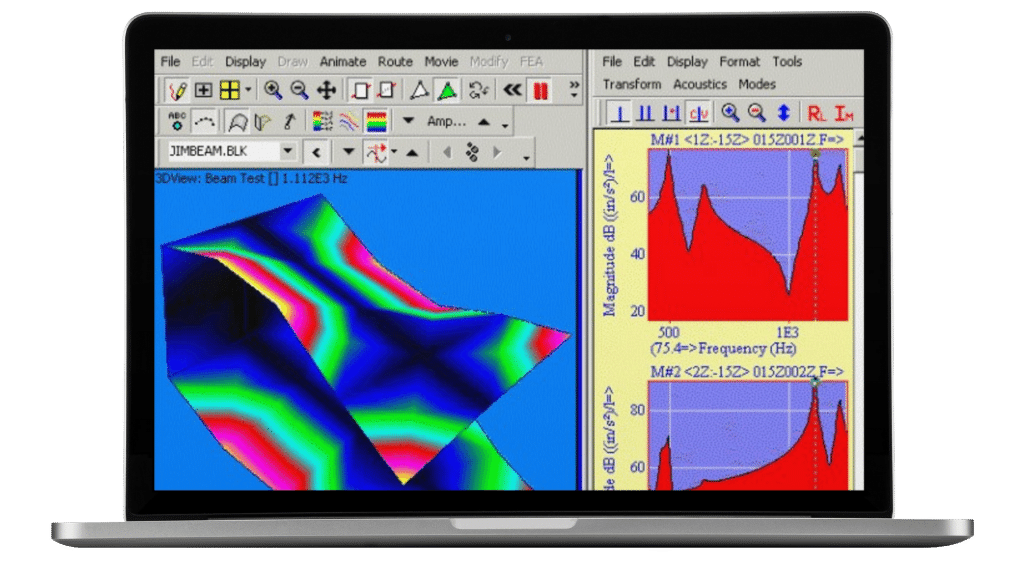

Curent Predictive Maintenance Technology

Conventional Predictive Maintenance (PdM) uses vibration analysis to provide early warning to predict imminent failure of machinery to maximize asset uptime, improve

product quality and reduce cost. Each machine has a unique vibration signature based

on its design. PdM is a process and uses analysis charts and graphic patterns like a

heart EKG. A proper analysis of the signature provides a wealth of information. This is

accomplished by installing vibration sensors at key locations on machines to monitor

the condition. The data is analyzed using proprietary software to assess the

machinery’s health.

There is an inherent problem with this process in that it requires an experienced and

costly analyst and considerable time in some instances to diagnose the issues. The

process is based on thirty-year-old technology and is labor intensive.

There are two approaches currently being used. First is periodic monitoring (roughly 85%) using portable data collectors and software for analysis. And the second is online continuous monitoring of critical and important assets (about 15%). The result is trended over time to detect a significant change in asset performance. In the first case, the analysis is based on periodic snapshot of an asset. It is relatively inexpensive but unreliable. For continuous monitoring permanent sensors are installed at key locations. The information is continuously sent to a central server using a proprietary network. Continuous monitoring is obviously advantageous but prohibitively expensive due to the significant cost of sensors. In addition, the current analysis method (algorithms) is mathematically limited and cannot provide self-diagnostics.

There are two approaches currently being used. First is periodic monitoring (roughly 85%) using portable data collectors and software for analysis. And the second is online continuous monitoring of critical and important assets (about 15%). The result is trended over time to detect a significant change in asset performance. In the first case, the analysis is based on periodic snapshot of an asset. It is relatively inexpensive but unreliable. For continuous monitoring permanent sensors are installed at key locations. The information is continuously sent to a central server using a proprietary network. Continuous monitoring is obviously advantageous but prohibitively expensive due to the significant cost of sensors. In addition, the current analysis method (algorithms) is mathematically limited and cannot provide self-diagnostics.

Happy Customers

0

+

Countries Served

0

+

Years Experience

0

+

Listening to you & your Machine, and answering with software

What PredictOS Offers

Unique Self-

Diagnosis

We offer specialized software for automatic asset deterioration and failure prediction, unmatched in the industry.

Decades of Algorithmic Expertise

Our algorithms, refined over three decades, set us apart from competitors, delivering accuracy and reliability.

Advanced Algorithm Mix

PredictOS blends physics-based models, AI-driven machine learning, and asset-specific digital twins for precise analysis.

Powerful Diagnostic Fusion

The software seamlessly integrates motor current signature analysis (MCSA) and vibration assessment for robust diagnostics.

Analyst-Free Operation

Eliminate the need for highly trained analysts; PredictOS empowers all levels of users to benefit from predictive maintenance.

Cost-Efficient Approach

MCSA combined with vibration analysis reduces sensor count, cutting costs and enabling SaaS application.

Paradigm

Redefined

Our methodology challenges the prevailing Predictive Maintenance paradigm, introducing an innovative, more effective approach.

Proven Field Performance

Rigorous beta testing, including simulations and real-world trials, has honed the algorithms, leading to automated diagnostics and bolstered confidence in results.

Who we are

Application Opportunities

Pivotal Role of PdM Tech in Industry 4.0

Amid the push for asset management, digitization, and automated maintenance driven by Industry 4.0, Predictive Maintenance (PdM) technology gains significance. Sensor-monitored assets transmit data to the Cloud, and digital twin models enhance predictive analytics with machine learning, aiming to forecast failure time. Existing solutions fall short in achieving this goal.

Vast Potential of PredictOS

PredictOS technology boasts wide applicability across various standard industrial and commercial machinery, including variable speed assets, compressors, and HVAC systems. This innovation addresses a broad market encompassing data centers, cold storage facilities, hospitals, and large commercial spaces, aligning with the rapidly expanding PdM market.

Get a Trial and Solutions Demo from us

Meet our team

The company has an experienced management team in taking new products from concept to the international market.

Dr. Suri Ganeriwala

C.E.O

Dr. Suri is a globally recognized Subject Matter Expert in machinery diagnostics and signal processing,

Nick Driver

Application engineer

Nick Driver holds a PhD in Experimental Physics and Nanotechnology with tech and software experience.

James Lowe

Developer

James Lowe has over thirty years of machine design and software development experience.

Dr. Rishi Ganeriwala

Software Engineer

Dr. Rishi Ganeriwala comes with programing experience in developing environmental and medical devices.

Robert Johann

Operation VP

Preston Johnson has over twenty-five years of experience in sales and marketing of PdM products.

Customer Reviews

(20,702 reviews)

★★★★★ Rated 5 out of 5

Aptent efficitur auctor turpis dictum nisi at diam integer ex. Interdum feugiat finibus curabitur lacinia leo auctor. Primis si libero conubia lacinia eu proin amet.

Aptent efficitur auctor turpis dictum nisi at diam integer ex. Interdum feugiat finibus curabitur lacinia leo auctor. Primis si libero conubia lacinia eu proin amet.

Aptent efficitur auctor turpis dictum nisi at diam integer ex. Interdum feugiat finibus curabitur lacinia leo auctor. Primis si libero conubia lacinia eu proin amet.

Contact Us

Office Address

8227 Hermitage Road Richmond, VA 23228

Call us

804-261-3300

Fax

804-261-3303

Email us

info@PredictOS.com

Send a message

Connect with us. Simply fill this form and we’ll get back to you.

Follow our social media

Our Clients